WORKS

Make quality high quality.

Challenge the evolution of technology.

Since our founding, Sanei continues to take on the challenge of manufacturing products that meet the needs of the present and future by matching the skilled craftsmanship that we have been engaged in manufacturing with modern science and technology.

In a world where high quality and high performance are commonplace, we contribute to all optical industries while sublimating and evolving all kinds of technology to satisfy our customers.

INTERVIEW

Designing high-quality,

easy-to-use jigs and tools

Position/Leader Joined in 2006

I have been involved in the production of jigs and tools since I first joined the company, but now I am mainly involved in the design and drafting of jigs and tools.

When designing jigs and tools, our first priority is to design jigs and tools that are easy to use while incorporating the customer’s requests based on discussions with the customer.

In addition, while honing my skill every day, I’m also conscious of the ease of manufacturing jigs and tools, so that I can quickly provide high quality products to our customers.

PRODUCTS

Product information

-

polishing plate

We can manufacture in R and diameter. We can perform Newton correction and process according to the shape you are using (screws, etc.).

-

Various plates

We can process a wide range of materials including FC, AL, BSBM, SUS, and resin.

-

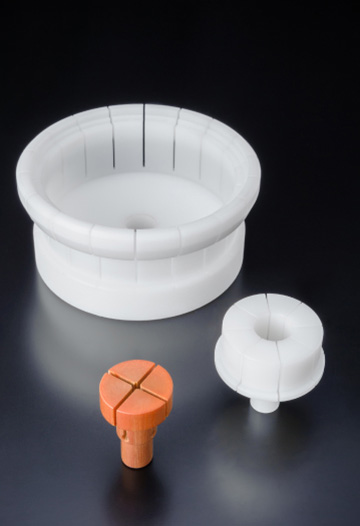

Lens holder production

The holder is manufactured according to the shape of the lens.

-

Chuck for roughing

We also correspond to the specifications of each company.

-

Other jigs and optical parts

We also handle various orders for polishing jigs and tools, so please feel free to contact us.

-

SUPPORT

Supporting the optical industry involved in polishing

Each company has different specifications. After a meeting, we will propose a jig that will satisfy your company and quickly provide high quality products to our customers.

FACILITY

Equipment introduction

・NC lathe [14 units]

・Compound NC lathe [3 units]

・Spherical surface processing machine [6 units]

・General-purpose lathe [3 units]

・General purpose milling machine [2 machines]

・Drilling machine [5 units]

・2D CAD [3 units]

・Image measuring machine [2 units]

PARTNER

Production partner company

- KASAHARA SEIKO Co., Ltd.

-

2222-12 Shimosuwa- Cho, Nagano, 393-0008

TEL.0266-27-0555 FAX:0266-27-0551